OMRON recently announced it is joining the EP100 , an international corporate initiative to improve energy productivity . In joining the initiative, OMRON commits to doubling the energy productivity of its Industrial Automation and Healthcare businesses by 2040. This will require the development of unique measures, aimed at reducing the energy consumption and improving the productivity of production factories. OMRON looks beyond improving its own energy productivity, as customers will be empowered to do the same through its specialized solutions and technologies.

1 An international corporate initiative in which companies with the goal of doubling the energy productivity of their operations (e.g., improving energy efficiency by 50%) participate. Abbreviation of "100% Energy Productivity," meaning doubling the energy efficiency (Energy Productivity) of a business.

2 Ratio of economic productivity to energy consumption. It is an indicator for Scope 1 and 2 of the company's business locations, with absolute energy consumption in the denominator and sales and value-added in the numerator, aiming to achieve both energy consumption reduction and economic growth.

Initiative to Improve Energy Productivity to Achieve Sales Growth while Reducing Energy Consumption

Initiative to Improve Energy Productivity to Achieve Sales Growth while Reducing Energy ConsumptionŃĆĆ

Society is currently facing a number of significant challenges. OMRON is committed to address those issues. To do so effectively and bring about the greatest impact, the company formulated a long term vision ('Shaping the Future 2030') and identified three main focus areas: climate change, societal aging, and the increasing wealth gap. OMRON sees these issues as growth opportunities for the organization and is working to resolve them through its own businesses.

A Long Term Vision 'Shaping the Future 2030'

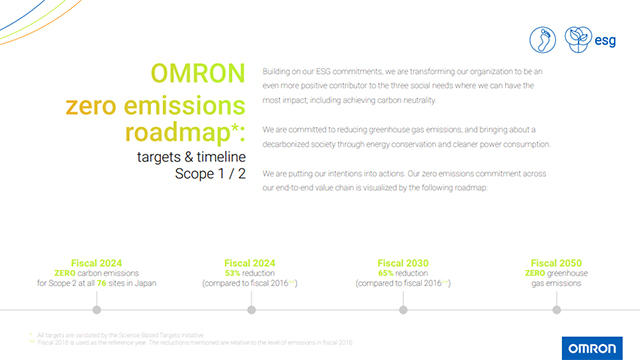

A Long Term Vision 'Shaping the Future 2030'OMRON is committed to reducing its environmental impact through various means. Its most important goal is to achieve carbon neutrality by 2050. To this end, the company set a target to reduce Greenhouse Gas (GHG) emissions from its own operations (Scope 1 and 2) by 53% in FY2024 and 65% in FY2030, compared to FY2016. To achieve these targets, OMRON is instituting a number of measures aimed at energy conservation and creation.

"By transforming our organization in the years to come, we aim to contribute to social needs; like achieving carbon neutrality. We are committed to reducing greenhouse gas emissions, and bringing about a decarbonized society through energy conservation and cleaner power consumption", says Yoshihito Yamada, President and CEO of OMRON Corporation.

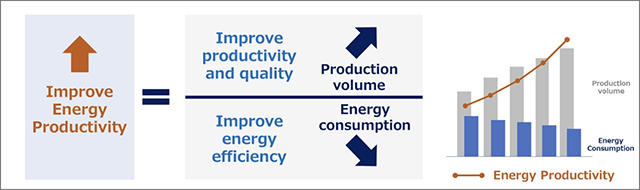

By joining the EP100, OMRON takes another decisive step to further its carbon neutrality ambitions and strengthens its efforts on the front of climate change by promising to double its energy productivity. To improve energy productivity, the amount of generated economic output needs to increase while the amount of consumed energy is lowered.

Increasing energy productivity is a very important measure in curbing the effects of climate change, as the world gradually transitions to renewable energy sources. OMRON's goal to double its energy productivity by 2040 means the company intends to double the amount of sales per Gigawatt Hour (Gwh). Doing so will achieve a reduction in energy consumption, while simultaneously boosting economic growth, in line with OMRON's long-term vision.

"OMRON's mission is to improve lives and contribute to a better society. We do this by empowering people through automation", says Robert Black, President, CEO and COO of OMRON Electronics. "We are pioneers, committed to solving social issues through business. Achieving carbon neutrality and accelerating efforts to realize decarbonization and growth while reducing environmental impact goes hand in hand with that goal, and is a part of our DNA."

ŃĆĆ

In order to address the social issue of climate change, OMRON is working on reducing carbon emissions at all 76 sites in Japan to zero. Accordingly, for more than a decade, OMRON's Industrial Automation business worked to increase the quality of its products and productivity of its production factories while limiting environmental impact. This is an ongoing effort, but significant strides have already been realized at the Ayabe factory (Ayabe City, Kyoto Prefecture) and other in-house factories. OMRON collects the insights required to innovate and develop solutions through monitoring of the production volume, quality, and energy consumption of its production factories, consistently evaluating opportunities for energy reduction.

This effort to expand energy conservation and energy creation measures is put into practice at the Ayabe factory, where several new initiatives have born fruit. For instance, many manufacturing companies started implementing measures to save energy in lighting, air conditioning, and other facilities, as they endeavor to decarbonize their factories. However, measures to enhance the energy efficiency of production facilities - which account for 70% of the total energy consumption of factories - tend to be put off due to concerns about the impact on quality and productivity. In response to this issue, the Ayabe factory introduced cutting-edge applications that achieve quality and productivity improvements as well as improved energy efficiency.

Ayabe Factory, Where Has Been Working to Improve Energy Productivity for More Than 10 Years

Ayabe Factory, Where Has Been Working to Improve Energy Productivity for More Than 10 YearsThe recently updated i-BELT Data Management Platform is one of the initiatives meant to improve energy efficiency and productivity. This new data-driven service streamlines the integrated management of diverse data, which has never before been utilized to bring about improvement on manufacturing floors, thus assisting users in tackling their issues both effectively and efficiently. This enables the ability to integrate energy data and productivity data to produce an indicator for energy productivity, which can be used to drive initiatives to achieve carbon neutrality. In order to encourage carbon neutrality across OMRON's entire value chain, this technology is also made available to our customers.

"The technologies and know-how cultivated through these efforts allow OMRON to lead the manufacturing industry in energy productivity improvement." Says Ryuichiro Takaichi, an engineer in OMRON's Industrial Automation Business (IAB), "But these products and services are not only used at our production sites. In fact, we provide the same innovative solutions to our customers; empowering them to address climate change and increase energy productivity at their own production sites."

ŃĆĆ

OMRON's Social Systems, Solutions and Service Business (SSB) is at the heart of the company's efforts to provide its customers with the groundbreaking solutions needed to decarbonize. So far, SSB has contributed to the adoption and implementation of solar power generation and storage batteries. Going forward, the business will contribute to the further application of renewable energy by eliminating instability in power generation using OMRON's advanced energy control technology. To date, this effort has translated into a cumulative shipped capacity of solar power systems of 10.8 GW.

Furthermore, OMRON is accelerating the development and provision of electronic components that contribute to energy savings, working to reduce the carbon footprint of its customers' manufacturing processes. This has the potential to bear fruit in several sectors, for instance the production of home appliances. OMRON's new products will contribute to a reduction in GHG emissions associated with the manufacturing of air conditioning systems, which have seen a rise in demand due to rising average temperatures.

"At OMRON, we innovate for a sustainable future by putting people and the planet at the forefront of our decisions and actions. We strive for a healthy, carbon neutral and inclusive digitalized society through automation that empowers people" says Yoshihito Yamada, President and CEO of OMRON Corporation.

ŃĆĆ

The social issue of climate change is not one OMRON can solve on its own. The company is therefore determined to provide the industry leadership needed to accelerate climate action, while working to create more resilient and sustainable automation together with its customers and partners across the value chain. This is especially important in light of the urgency for agreement at the United Nations Framework Convention on Climate Change Conference of the Parties (COP27), where the next steps in the fight against climate change will soon be set.